Multi-Wavelength Diode Laser Modules

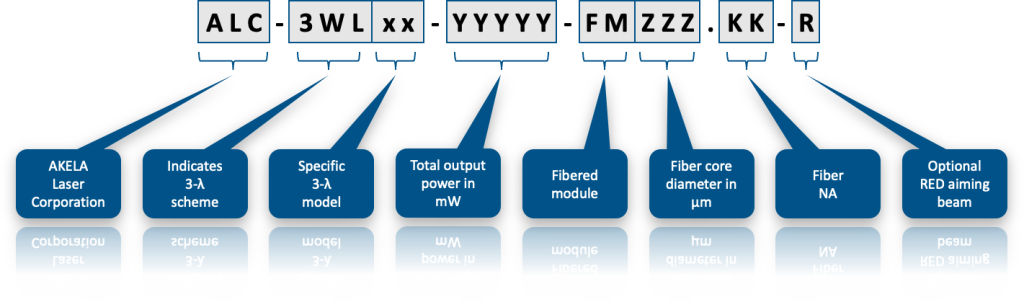

Part number structure

Examples of possible combinations

Given the numerous possible combinations, we provide examples of various configurations along with a selection of actual data sheets.

Sample Data Sheets

What is a Three-Wavelength Diode Laser Module?

A three-wavelength diode laser module is a system designed to produce three distinct wavelengths of light within a single device. This eliminates the need for multiple separate lasers, making it easier to switch between or combine wavelengths in various applications.

Three diode lasers that emit different wavelengths can be combined through optical components such as dichroic mirrors or fiber combiners. The result is a unified output with multiple wavelengths available for use either independently or simultaneously.

Key Benefits of Three-Wavelength Diode Laser Modules

- Space-saving Design: Three distinct laser sources in one compact unit.

- Increased Efficiency: Simplifies system design and reduces component count.

- Flexible Operation: Enables switching or simultaneous use of multiple wavelengths.

- Improved Accuracy: Provides stable and consistent output across all wavelengths.

- Cost Savings: Reduces the overall system cost compared to using three separate lasers.

Due to these advantages, many industries consider three-wavelength diode laser modules essential to their workflows.

How to Choose a Three-Wavelength Diode Laser Module Manufacturer

Selecting the right three-wavelength diode laser module manufacturer is critical because the quality, reliability, and customization options of the module impact your entire system’s performance.

Many manufacturers offer similar products, but differences in technology, quality control, and customer service can significantly impact the final result.

What to Look For in a Manufacturer?

- Proven Expertise: A strong background in photonics and laser design.

- Customization Options: Ability to tailor wavelength combinations, power levels, and interfaces.

- Quality Control: Strict testing for output power, wavelength accuracy, and durability.

- Customer Support: Responsive technical assistance from inquiry to post-sales.

- Compliance: Modules that meet industry standards and safety regulations.

- Timely Delivery: Ability to meet your project deadlines with dependable shipping.

- Competitive Pricing: Fair cost structures that don’t compromise quality.

Choosing a manufacturer that checks all these boxes ensures that your investment in a three-wavelength diode laser module pays off in terms of both performance and reliability.

Applications of Three-Wavelength Diode Laser Modules

Three-wavelength diode laser modules have a broad range of applications across different sectors.

Medical and Scientific Research

- Fluorescence Microscopy: Using multiple wavelengths to excite different fluorophores, allowing detailed biological imaging.

- Spectroscopy: Enhanced analysis through simultaneous multi-wavelength detection improves the accuracy of chemical and material identification.

- Optogenetics: Precise control of biological processes through targeted neural stimulation using varied light wavelengths.

These modules simplify complex experimental setups by reducing the number of laser sources needed.

Industrial and Engineering

- Material Processing: Cutting, welding, and marking materials that respond differently to various wavelengths.

- Metrology: Precise measurements that require different laser wavelengths to analyze surface profiles or structural properties.

- Telecommunications: Wavelength-division multiplexing (WDM) technology uses multiple wavelengths to increase bandwidth in fiber optic communications.

Environmental and Agricultural

- Remote Sensing: Using multiple wavelengths to monitor atmospheric gases or vegetation health.

- Agriculture: Assessing crop conditions with multi-wavelength laser scanning systems.

The flexibility of three-wavelength diode laser modules makes them valuable in both established and emerging industries.

Advantages of Using Three-Wavelength Diode Laser Modules

Simplified System Architecture

By combining three laser sources into a single module, system complexity is significantly reduced.

- Fewer optical components to align and maintain.

- Reduced power supply and cooling requirements.

- Enhanced portability for mobile or compact setups.

- Easier system integration saves design time and reduces errors.

Enhanced Performance and Flexibility

- Quick switching between wavelengths without hardware changes.

- Ability to use multiple wavelengths simultaneously for complex tasks.

- Customizable output power and modulation options allow fine control.

Reliability and Longevity

High-quality modules feature robust thermal management to maintain stable output and extend component life. This means fewer interruptions and lower maintenance costs over time.

Technical Features to Consider

When choosing a three-wavelength diode laser module, consider these technical details:

- Wavelength Range: Typical modules cover visible to near-infrared ranges (e.g., 405 nm, 532 nm, 650 nm).

- Output Power: Depending on the application, power can range from milliwatts to watts.

- Beam Quality: Single-mode or multimode operation affects focus and precision.

- Modulation Capability: Supports analog or digital modulation for dynamic control.

- Fiber Coupling: Modules may come with fiber output for easy integration.

- Cooling Method: Thermoelectric cooling ensures temperature stability.

Understanding these features will help match the module to your project needs.

How to Get Your Three-Wavelength Diode Laser Module In the USA

Ordering a three-wavelength diode laser module in the USA is straightforward when working with a trusted manufacturer. You can:

- Review available standard models online.

- Request a custom solution if your project has unique needs.

- Get expert advice to select the ideal configuration.

- Benefit from timely shipping and responsive customer service.

Working with a reliable manufacturer ensures you receive a module that fits your technical needs and budget.

The three-wavelength diode laser module is a powerful tool that supports complex tasks requiring multiple wavelengths from a single device. Choosing the right three-wavelength diode laser module manufacturer ensures you receive a product designed with precision, reliability, and adaptability.

Ready to integrate advanced laser technology into your systems? Contact Akela Laser today to discuss your needs or book a consultation with our laser technology experts.

Frequently Asked Questions

Available wavelengths typically range from the visible to the near-infrared, but custom configurations are often possible, depending on the manufacturer.

Yes, many modules offer customizable power levels to match specific application needs.

Most modules are designed for easy integration, but verifying compatibility is recommended.Accordion Content

High-quality modules are built for long-term operation with robust thermal management systems.

Yes, reputable manufacturers provide custom options to fit precise technical requirements.

They are widely used in healthcare, manufacturing, telecommunications, and research.

Always wear appropriate eye protection and follow operational guidelines specific to laser use.

Yes, most manufacturers offer ongoing support for setup, troubleshooting, and maintenance.