High-power diode lasers offer efficiency, longevity, and versatility for diverse industrial tasks.

Semiconductor diode lasers are compact, inexpensive, and offer an incomparable level of customization of the output power, wavelength, and beam delivery. These properties make them very attractive for diverse applications in medicine and biology. AKELA offers a wide selection of the highest quality diode laser products, including fiber-coupled laser diode modules, multi-wavelength diode laser modules, and direct beam modules. All AKELA products can be configured with optional red or green pilot beams, fiber sensor, blast shield, and power and temperature sensors.

What Are Industrial High-Power Laser Solutions?

Industrial high-power laser solutions refer to laser systems designed to deliver intense, focused beams of light capable of cutting, welding, marking, and processing a wide range of materials. These lasers play a crucial role in various industries, including automotive, aerospace, electronics, and others.

High-power lasers are valued for their:

- Precision: Allowing detailed and exact cuts or engravings.

- Speed: Faster processing compared to traditional mechanical methods.

- Versatility: Suitable for metals, plastics, ceramics, and composites.

- Durability: Designed for continuous operation in harsh environments.

At the core of these solutions are high-power laser diode modules, which provide the necessary energy output with efficiency and reliability.

Choose the Right High-Power Laser Diode Manufacturer

Selecting a trusted high-power laser diode module manufacturer is crucial for obtaining reliable and durable industrial laser solutions. Not all manufacturers provide the same level of quality or service, so it’s essential to consider several factors before making your choice.

Key Considerations When Choosing a Manufacturer

- Technical Expertise: Look for manufacturers with a strong background in laser diode technology.

- Customization: The ability to offer tailored solutions to meet specific power, wavelength, and cooling needs.

- Quality Assurance: Strict testing to ensure each module meets performance standards.

- Customer Support: Responsive assistance for product selection, integration, and after-sales service.

- Compliance: Modules that follow safety and industry regulations.

- Production Capacity: Ability to deliver orders on time, whether small or large scale.

Selecting the right manufacturer can significantly impact the efficiency and lifespan of your laser system.

Features of High-Power Laser Diode Modules

Understanding the components that make up high-power laser diode modules helps in appreciating their value and capabilities.

Typical Characteristics:

- Output Power: These modules often deliver power ranging from several watts to hundreds of watts, depending on the application.

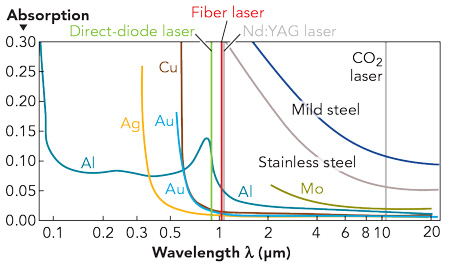

- Wavelength: Available in various wavelengths from visible to infrared, suited for different materials and processes.

- Beam Quality: Modules can be designed for single-mode or multimode output, directly affecting focus and precision.

- Cooling System: Thermoelectric or water cooling options to maintain optimal performance and prevent overheating.

- Modulation: Support for analog or digital modulation to dynamically control laser output.

- Fiber Coupling: Some modules come with fiber outputs for flexible integration into complex systems.

Advantages of High-Power Laser Modules

- Compact Size: Smaller than traditional laser sources, simplifying system design and integration.

- Energy Efficiency: Reduced power consumption compared to other laser types, leading to cost savings.

- Longevity: Designed for extended operation with minimal degradation over time.

- Easy Integration: Compatible with existing industrial automation systems, streamlining implementation.

Applications of Industrial High-Power Laser Solutions in the USA

The reach of high-power laser technology extends across various industries, from laser material processing to surgical equipment, each benefiting from its unique properties.

Manufacturing and Material Processing

- Cutting: Precise and rapid cutting of metals, plastics, and composites.

- Welding: Creating strong and clean joins without the need for additional materials.

- Marking and Engraving: Applying permanent identification or decorative designs on products.

- Surface Treatment: Hardening or cleaning surfaces without mechanical contact.

Aerospace and Automotive

- Component Fabrication: Manufacturing parts with tight tolerances.

- Inspection Systems: High-resolution laser-based measurement and quality control.

Electronics Industry

- Semiconductor Processing: Micromachining and wafer marking.

- PCB Manufacturing: Drilling and patterning with high precision.

Medical and Research Fields

- Laser Surgery Tools: High precision cutting with minimal tissue damage.

- Scientific Instruments: Laser excitation and spectroscopy.

Why Industrial High-Power Laser Solutions in the USA Are Trusted

The USA is home to some of the most advanced laser technology companies and research facilities. Choosing local industrial high-power laser solutions offers distinct advantages:

- Advanced Technology: Access to the latest laser innovations and research breakthroughs.

- Regulatory Compliance: Products are designed to meet strict safety and quality standards.

- Fast Support: Easy access to technical support and maintenance.

- Customization: US manufacturers often work closely with clients to develop bespoke solutions tailored to specific needs.

Benefits of Using High-Power Laser Modules

Enhanced Productivity

- Faster processing times directly increase output and alleviate bottlenecks.

- Minimal downtime is achieved through a robust design and the use of reliable components.

Cost-Effectiveness

- Reduced need for consumables like gases or mechanical parts.

- Lower energy costs due to efficient diode laser technology.

- Long service life reduces replacement frequency.

Improved Quality

- Precise beam control ensures clean cuts and consistent markings.

- Lower heat-affected zones minimize material distortion, preserving material integrity.

How to Choose Your Industrial High-Power Laser Solutions in the USA

Selecting the right solution begins with understanding your application requirements and consulting with experienced manufacturers. A dependable high-power laser diode module manufacturer can guide you through:

- Defining power and wavelength needs.

- Choosing appropriate cooling and modulation options.

- Integrating the module into your system.

- Providing ongoing technical support.

Industrial laser technology is transforming manufacturing and research through precision and power. Choosing industrial high-power laser solutions in the USA, paired with high-power laser diode modules of the highest quality, ensures that your projects benefit from the best performance and reliability.

Ready to upgrade your operations or develop a new laser-based system? Contact us today to consult with experts and book your custom industrial laser solution.

Frequently Asked Questions

Industries such as automotive, aerospace, electronics, medical, and manufacturing widely use these laser solutions.

Power can range from a few watts up to several hundred watts, depending on the module design.

Yes, many manufacturers offer tailored options for wavelength, power, cooling, and modulation.

Yes, they consume less energy than many other laser types, making them cost-effective in the long run.

Thermoelectric cooling is standard, with some high-power modules using water cooling systems for heat management.

When sourced from reputable manufacturers, these modules are designed for long operational lifespans and stable performance.

Yes, appropriate safety protocols, including the use of eye protection and working in controlled environments, should be followed.

Consider expertise, product quality, customization options, support services, and delivery capabilities.