High-Power Diode Lasers for Precision, Performance, and Reliability

AKELA Laser designs and manufactures high-power diode laser modules known for their efficiency, durability, and adaptability. Semiconductor diode lasers provide a compact solution with exceptional control over output power, wavelength, and beam delivery, making them ideal for demanding applications in industry, medicine, and biotechnology. Our product line includes fiber-coupled modules, multi-wavelength systems, and direct beam configurations. Each module is available with customizable features, including red or green pilot beams, fiber sensors, blast shields, and integrated power and temperature sensors.

Industrial laser technology is transforming manufacturing and research through precision and power. Choosing a trusted laser diode module manufacturer, paired with high-power laser diode modules of the highest quality, ensures that your projects benefit from the best performance and reliability.

Ready to upgrade your operations or develop a new laser-based system? Contact us today to consult with experts and book your custom industrial laser solution.

Frequently Asked Questions

A reliable manufacturer should have proven technical expertise in laser diode technology, offer customization for power, wavelength, and cooling needs, and maintain strict quality assurance procedures. Look for responsive customer support, compliance with industry safety standards, and the ability to meet both small and large-scale production requirements.

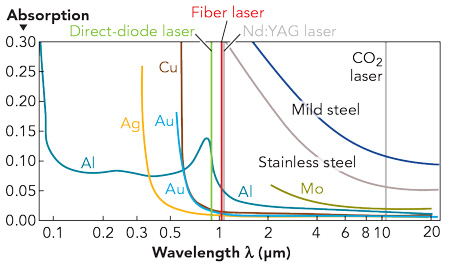

Typical features include output powers from a few watts to hundreds of watts, wavelengths ranging from visible to infrared, thermoelectric or water cooling systems, analog/digital modulation options, and optional fiber-coupled outputs for flexible integration.

They offer compact size for easier integration, high energy efficiency that reduces operating costs, long operational lifespans, and compatibility with existing automation systems, making them ideal for demanding industrial environments.

Applications span manufacturing, aerospace, automotive, electronics, and medical fields. These include cutting, welding, engraving, semiconductor processing, PCB manufacturing, laser surgery, and scientific research.

They are used for precision cutting of metals and plastics, strong and clean welding, permanent marking/engraving, and surface treatments like hardening or cleaning without mechanical contact.

US manufacturers provide access to the latest laser technology, adhere to strict safety and quality standards, and offer faster technical support. They also frequently collaborate with clients to design custom laser solutions.

They enable faster processing times, reduce production bottlenecks, and minimize downtime through robust designs and high-quality components.

Yes. They have lower energy consumption than other laser types, require fewer consumables, and have long service lives—reducing both operating and replacement costs.

Their precise beam control ensures clean cuts and consistent markings, while minimizing heat-affected zones to preserve the integrity of the processed materials.

Absolutely. Akela Laser can tailor power output, wavelength, cooling systems, modulation capabilities, and coupling options to meet the exact needs of your process or system.